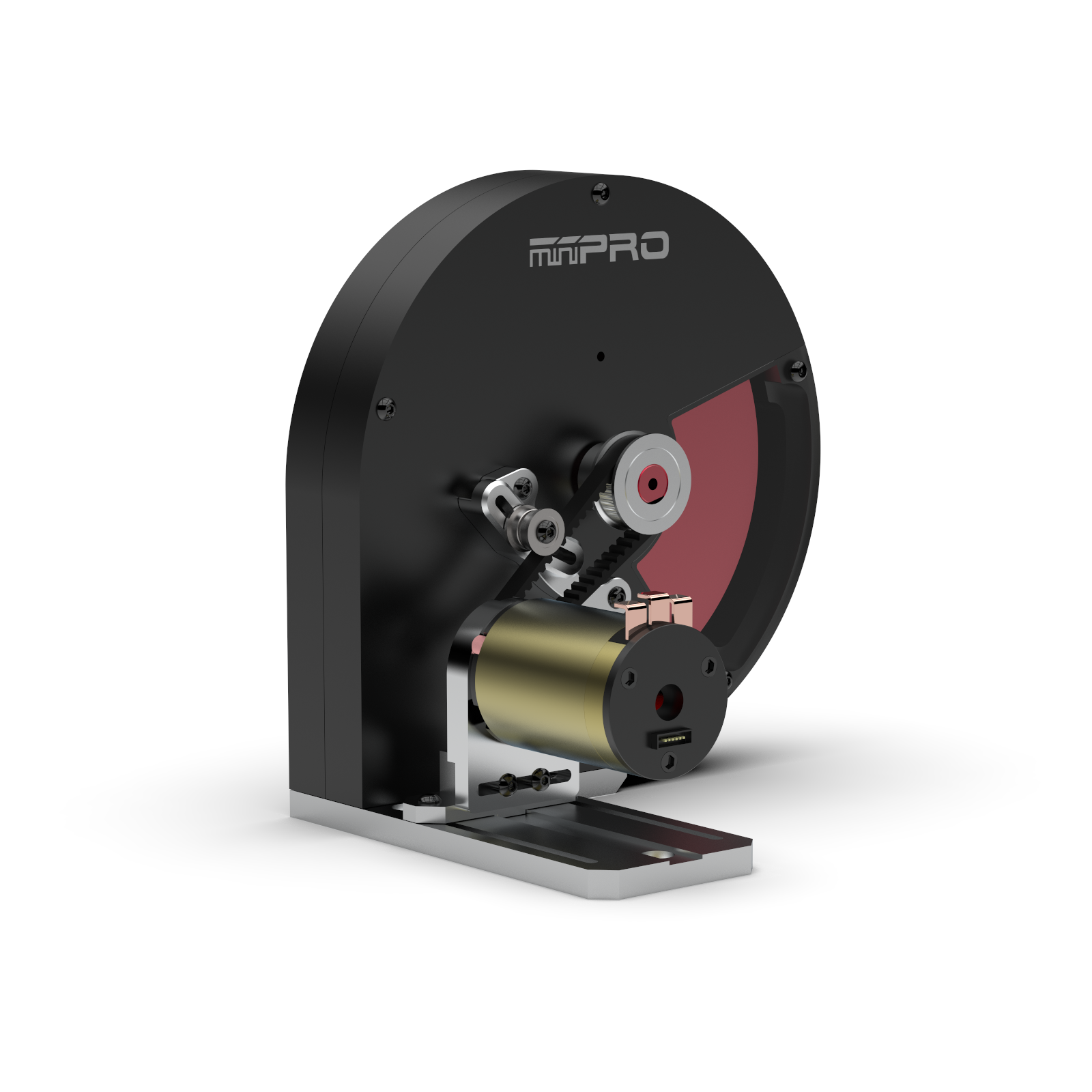

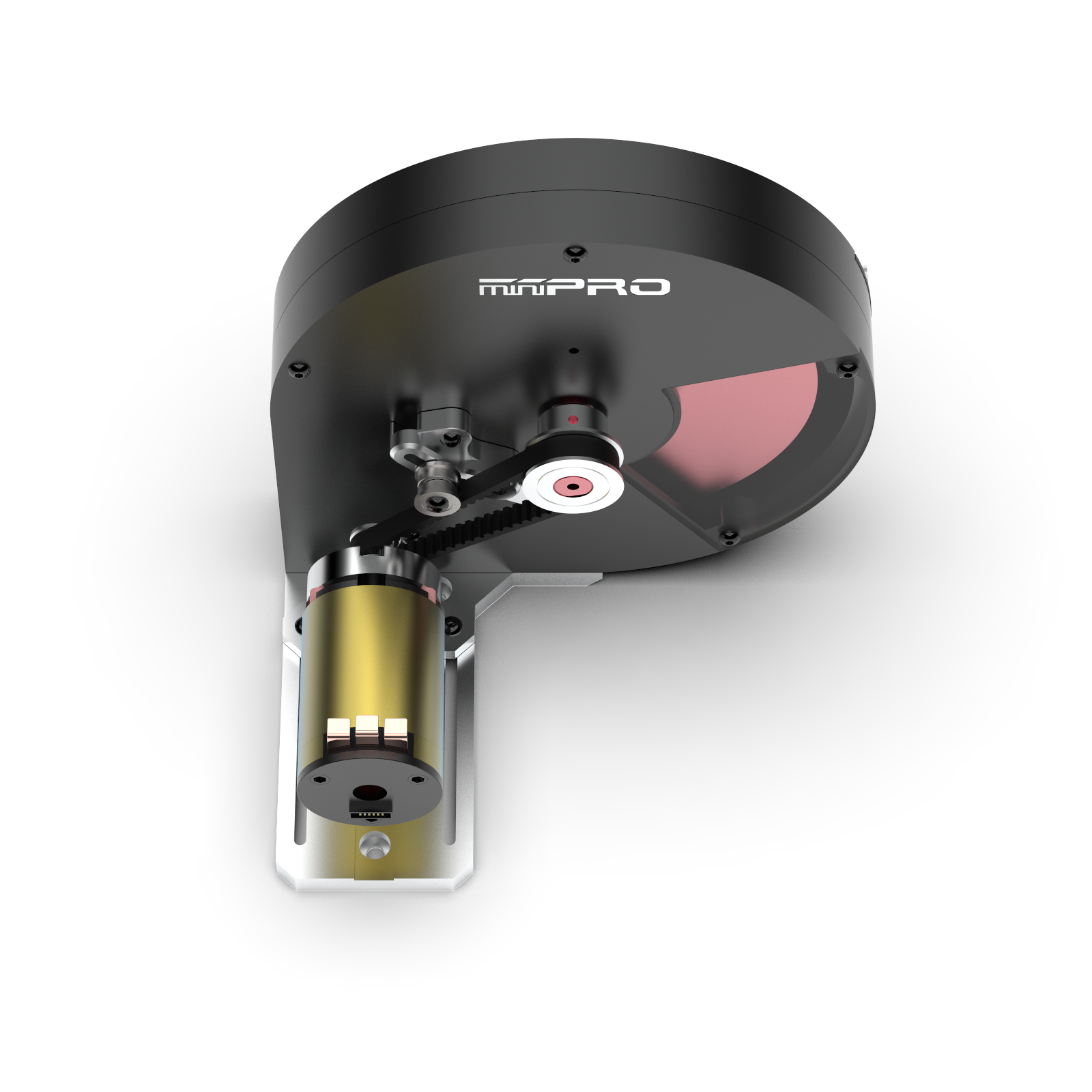

MINIPRO’s R/C Car Inertia Motor Dynamometer (Dyno) was designed for the testing all types of R/C motors, brushed or brushless. The load on the motor is produced by the inertia flywheel unit - a high quality 6061 aluminum frame cover around the flywheel to protect from high rpm speeds; and an embedded dyno board to accurately measure the acceleration of the DUT (device under test).

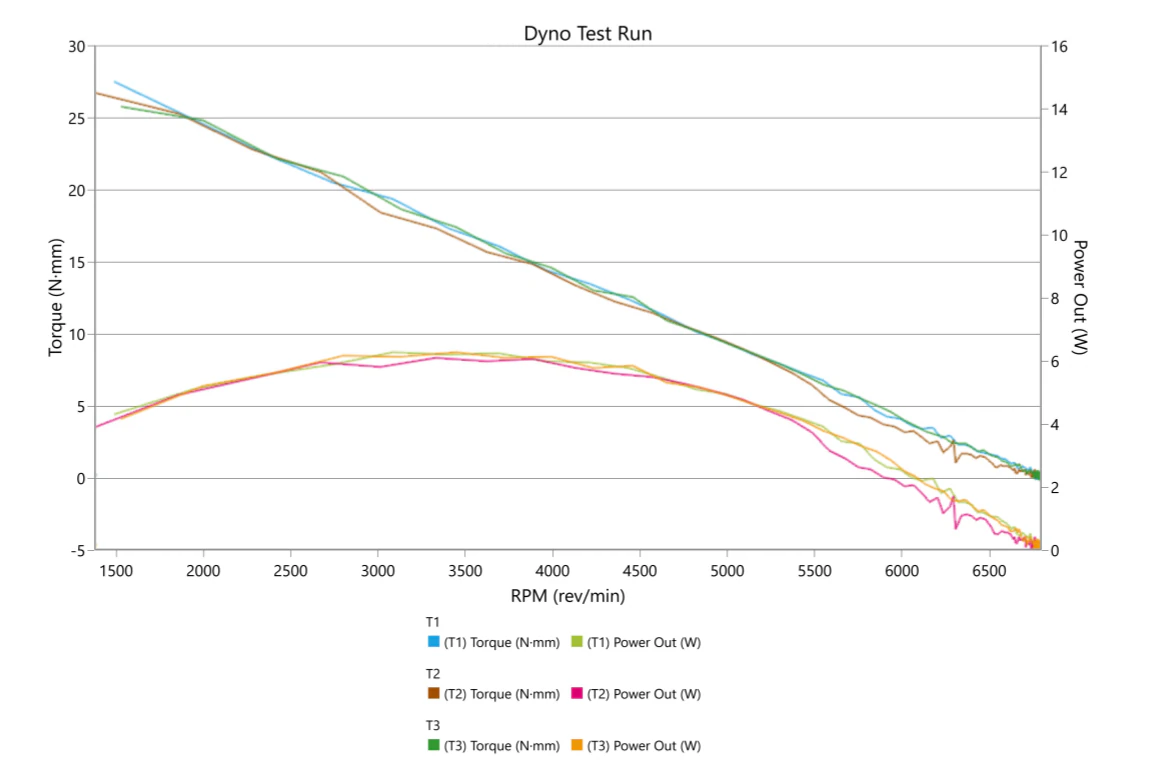

The dyno is coupled to a motor holder via a pulley and belt to accelerate the inertial mass (flywheel). Our embedded dyno board takes the flywheel’s inertia (resistance of an object to a change in its state of motion), and measures the rate it takes to accelerate it and calculates the output power and torque of the DUT. Our dyno repeatedly measures and calculates power in small increments to produce an accurate graph on a PC of the motor’s power characteristics.

Precise, otherwise known as "Repeatability" is what you want in a dyno, that means test the same electric motor time after time and get the same results. Our dyno is capable of repeatable test results using the Throttle Controller Board (sold separately).

MEASUREMENTS:

- Motor RPM

- Kv (rpm/v)

- Torque

- Power-In (requires voltage & current sensor)

- Power-Out

- Up to three temperature readings (requires temperature sensor)

- Voltage (requires voltage & current sensor)

- Current (requires voltage & current sensor)

- mAh (requires voltage & current sensor)

- Efficiency (requires voltage & current sensor)

FEATURES:

-Motor Torque: up to 250 mN·m

-Motor Power: 500W burst power (168W continued)

-Speed: up to 40,000rpm

-Voltage: up to 2S/8.4V

-Current: up to 200A burst current (50A continued)

-Low residual torque

-Low friction ball bearings

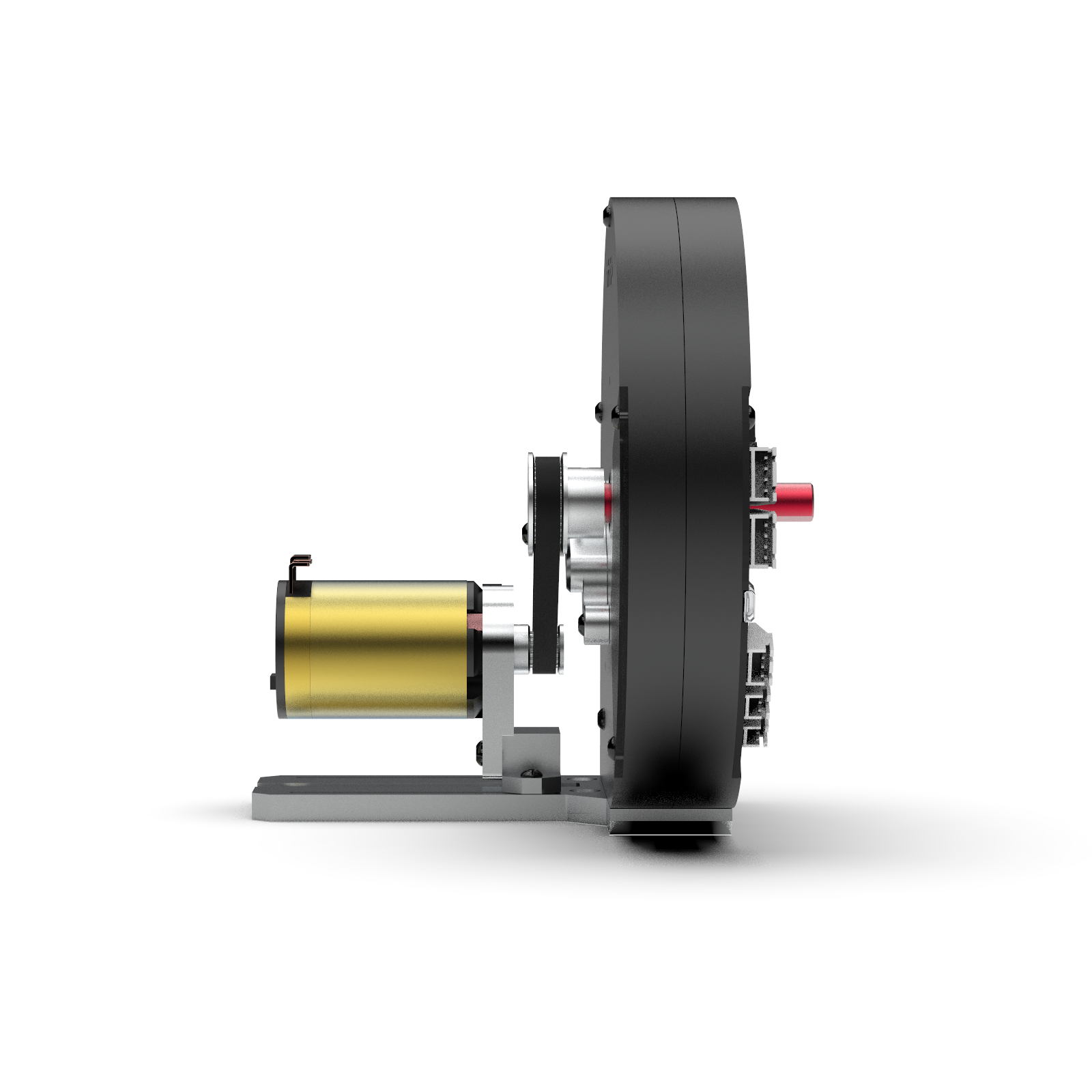

-Built-in dyno controller board to measure RPM, Speed, RPM/V (Kv), Torque, Power and Efficiency.

-Load adjustability by using different flywheel(s)

-Low maintenance

-Close loop control via Throttle Control Sensor (sold separately)

SAFETY FIRST

The dyno uses a high quality 6061 aluminum frame cover around the flywheel to protect from high rpm speeds produced by your motors. Yet we still offer the ability to see the flywheel spinning action by adding a clear window screen.

FLYWHEEL (VARIABLE LOAD)

The dyno uses the engine to simply accelerate a flywheel (variable load). We calculate the mechanical power and mechanical torque of the motor by knowing the flywheels inertia (resistance of an object to a change in its state of motion) and it's acceleration. We offer different sizes and materials to best suit your motor application. Additional flywheels can be purchased separately.

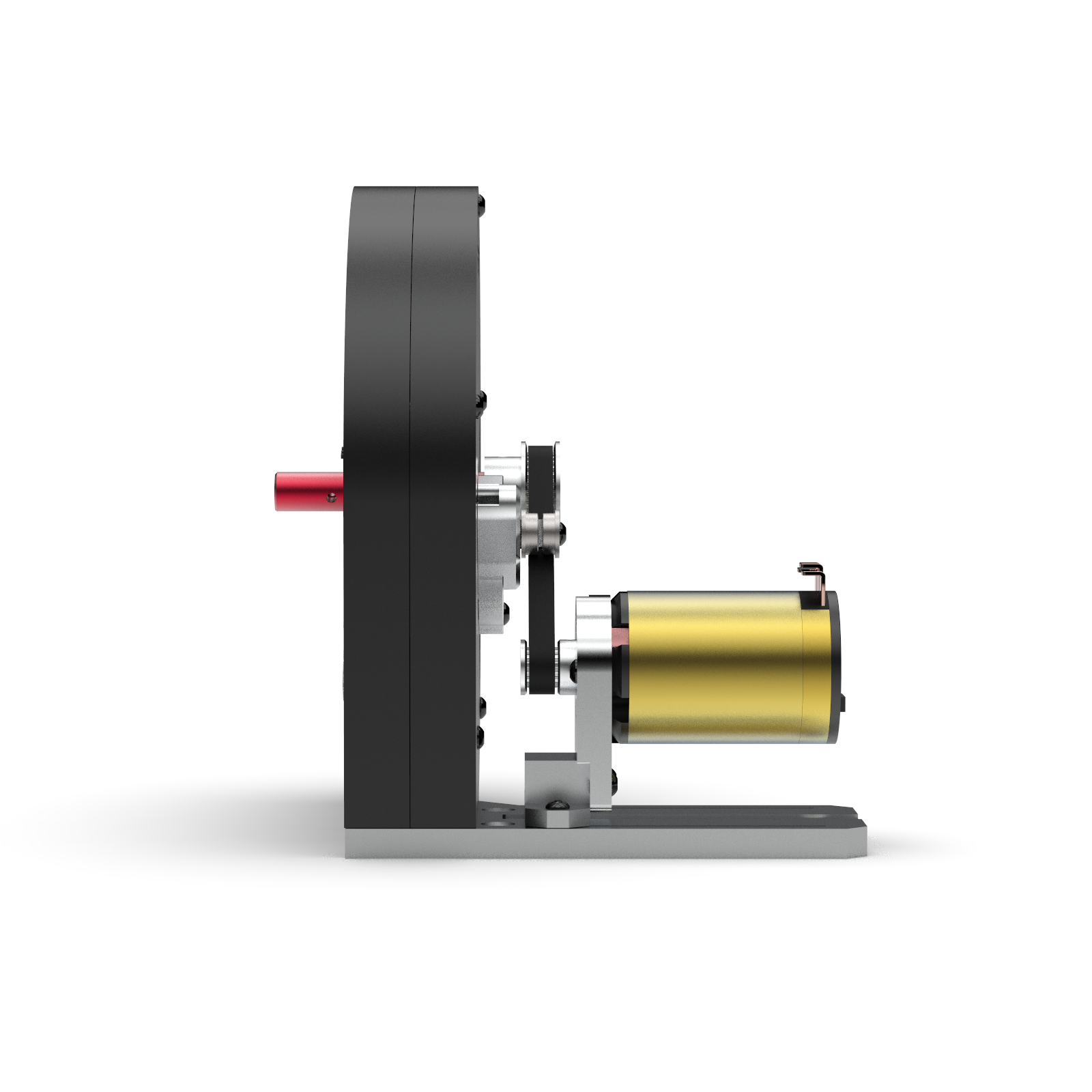

FIXED BASE

Screw into baseboard to securely fasten the dyno. Screw #3 is optional.

MOTOR HOLDER

MOTOR PULLEY

A pulley is installed in the test motor to includes two size of pulleys: 3.175mm, and 5mm bore to use with Outrunner and 540/550 sized motors. Additional size pulleys can be purchase separately.

PREMIUM BALL BEARINGS

The flywheel incorporates a set of 2 high-speed, black-sealed, steel ball-bearings throughout the assembly to ensure low friction and maximum efficiency. Optional ceramic bearings can be purchased separately.

INCLUDES:

(1) Flywheel Unit with selected options

(1) 540/550 Motor Holder with hardware

(1) Software License Key (1 PC license)

(1) Micro USB Cable

REQUIRES:

(1) Windows 10 PC

(1) Base plate to securely install the dynamometer

IMPORTANT: Voltage/Current sensor is required to measure voltage, current, power-in and efficiency. Throttle Control Sensor is required to control your ESC with the software. We reserve the right to change the color(s) of any component(s) of the dyno without prior notice.